Gelatin drying process

First of all, the preparation of edible gelatin starts with the selection of raw materials. Then the gelatin solution goes through alkali treatment, washing, acid treatment and washing.

Secondly once the raw material is ready, the gelatin solution can be washed from the solid particles, oils and salts after a continuous extraction process with water at a controlled temperature, as follows:

Centrifugation: Separation of fibers and strange materials is obtained from gelatin solution by using centrifugation equipment at approximately 6000RPM.

First clean filtration: Use diatomite as filter aid to retain particles and dirt.

Ion exchange: The ash in gelatin is removed from the skin gelatin liquid by a cationic column, and the acidity is pH regulated by an anion column at this stage.

Second filtration: Concentrate the gelatin liquid through the membrane. The second filtration is to make the concentrated gelatin liquid brighter.

Once the gelatin solution is filtered clean, MINJIE evaporator can be used for a high concentration process, which is then cooled by expansion in the separator. Gelatin is later on passed through a sterilizer (a heat exchanger of previously filtered direct steam) for four seconds at 138 ° C to eliminate pathogen bacteria from the gelatin liquid.

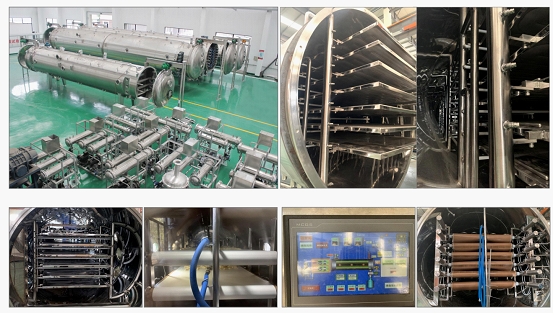

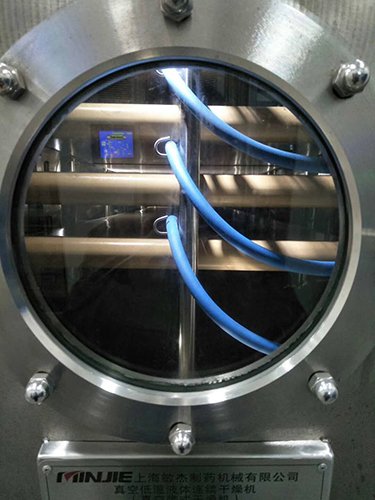

The gelatin liquid pumped into the dryer will move forward with the belt and be dried with MINJIE vacuum belt dryer. It bubbles due to the evaporation under vacuum and keeps taking away water and heat. Thus the material becomes loose and porous. The dryer has several heating zones and one cooling zone with temperature adjustable. The discharge end is equipped with scraper and cutting device, transport the dried material to pre-crushing and drop into the discharge tank and the fine crusher.

All processes are controlled by PLC, the dryer is also equipped with CIP on-line automatic cleaning system.

Compared with traditional drying method, the main advantages of Vacuum Belt Dryer are as follows:

- Continuous feed-in and discharge in vacuum state

- Complete the drying, crushing, granulating process under vacuum condition

- Automatic, continuous and pipelining drying process

- High product quality and ingredient preservation

- Drying temperature adjustable 20℃-150℃

- Parameter set as per different materials

- Continuousdischarge of dry powder after 30-60 minutes

- Recycling of dry powder can be up to 99%

Recycling of organic solvent, no discharge, no pollution1/3 operation cost of vacuum oven and spray dryer

- Suitable for drying of thermal sensitive, high sugar and high viscosity material

- Vacuum crushing technology, avoiding moisture re-absorption, loss and pollution

- Low labor cost, 2 operators at most

- No pollution of dust and flavor

- PLC automatic control system

- CIP automatic on-line cleaning system

- Meet the requirement of GMP

SHANGHAI MINJIE has become a leading manufacturer of Vacuum Belt Dryer & Evaporator since established in 1998.

For any enquiries, please contact: Caroline LI

Email address: globalsales1@shmjjx.com

Mob # /Whatsapp: +86 183-0190-2739