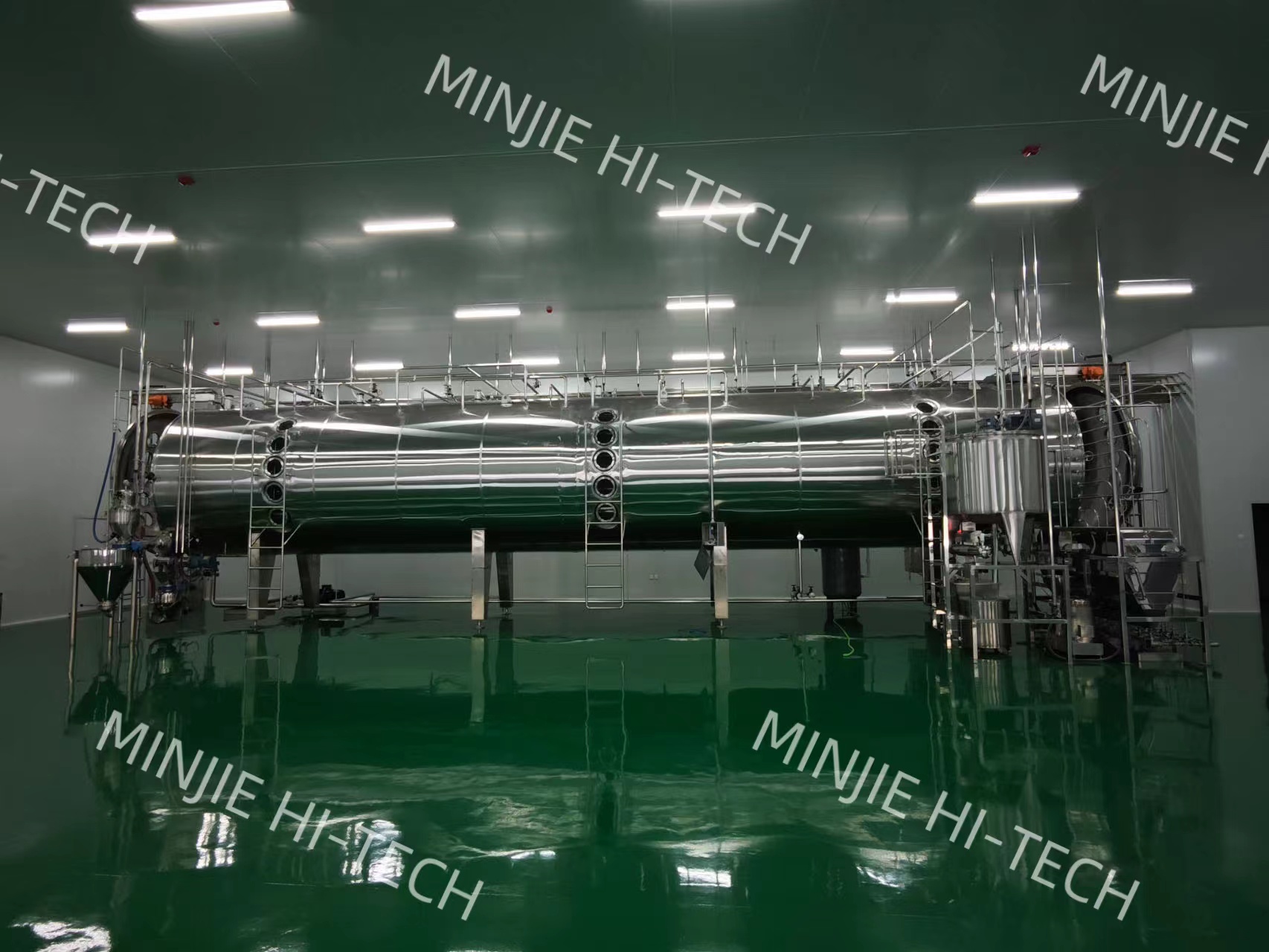

Vacuum belt dryer for Camel milk is a low-temperature dryer successfully developed for heat-sensitive materials. In order to protect the nutrients contained in camel milk, such as probiotics, yeasts, etc. which are heat-sensitive, therefore traditional drying equipment cannot be used during the drying process, but a low-temperature dryer developed by Shanghai Minjie.

Features of Vacuum belt dryer for Camel milk: This equipment is a contact-type vacuum drying equipment with continuous feeding and continuous discharging. The material to be dried passes through the conveying mechanism directly into the inside of the dryer under high vacuum, and is spread on drying belts in the dryer, a special rubber roller driven by a motor drives the drying belt to move along the barrel of the dryer at a set speed. Under each drying belt, there are three independent heating plates and one cooling plate and the drying belt are closely attached to the heating plate and the cooling plate, and the energy required for drying is transferred to the material by means of contact heat transfer.

Before using the camel milk belt dryer, you need to start the equipment to run, vent the air, adjust the required vacuum and temperature through the display screen, and wait for the vacuum and temperature in the cylinder to meet the requirements before feeding. If feed the material just after starting up, the material can not be dried well in the air. And the vacuum can keep the material free of bacteria and deterioration. Therefore, it is necessary to ensure that the required vacuum level in the cylinder is obtained before arranging the feeding.