Zero emissions target

In December 11, 2020, at the capital Brussels of Belgian, the commission announced “European green agreement” on climate change, put forward by the year 2050 the European Union to take the lead on a global scale to realize net zero emissions target, and identify the specific action roadmap, covering almost all areas of the economy, especially in transportation, energy, agriculture, construction and steel and cement, information and communication technology, textile and chemical industries.

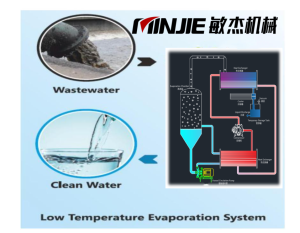

Some industries realize their current situation and start to make effort on energy saving and zero emmission, such as Power Plant desulfurization, petrochemical industry, coal chemical industry, electroplating industry, paper industry and pharmaceutical industry etc. A double effect energy saving evaporator plays more and more important role and solve difficulties and puzzles for these industries.

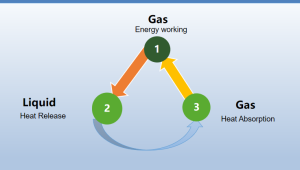

Referring to the refrigeration principle, the energy-carrying medium completes the continuous cycle of gas→liquid→ gas in the closed circulation system. During the phase change process, the medium realizes heat release and heat absorption. The heat released is used for the heating and evaporation of the material liquid, while the heat absorbed comes from the condensation heat of the secondary steam generated by the evaporation of the material liquid. The liquid concentration, solvent evaporation and solvent recovery can be realized through the use of both hot and cold energy.

APPLICATION SCOPE of ENERGY SAVING EVAPORATOR

The energy saving evaporator is widely used in the dehydration process of pharmaceutical, food, chemical, biological, environmental protection and other industries,wastewater treatment recovery, recycling and reuse (water reuse & waste heat recovery); Chemical concentration and reuse (papermaking, chemical wastewater, power battery, caustic soda, etc.); Leachate treatment (landfill, waste incineration power plant, kitchen recycling plant, etc.); Petrochemical industry; Fermentation industry; Corn starch processing industry; Sugar and salt industry wine industry; Dairy and other industries; Food and drug industry (food and drug wastewater, jam concentration, traditional Chinese medicine concentration); Bottled water and medical water (potions for injection, bottled water, etc.); Seawater desalination (such as: urban water supply, ships, oil exploration platforms, outlying island resorts).

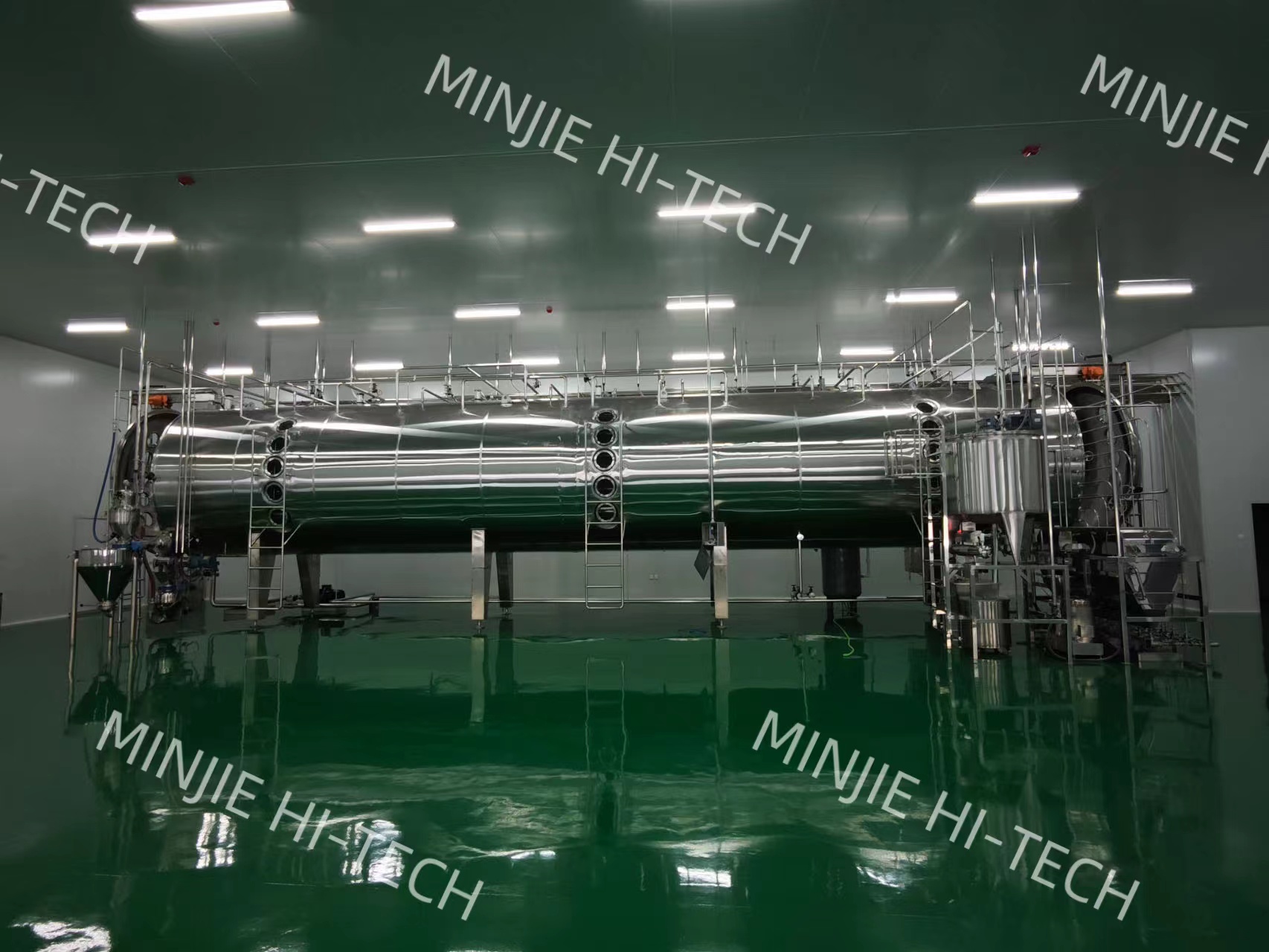

SHANGHAI MINJIE has become a leading manufacturer of Vacuum Belt Dryer & Evaporator since established in 1998.

For any enquiries, please contact: Caroline LI

Email address: globalsales1@shmjjx.com

Mob # /Whatsapp: +86 183-0190-2739