The results of drying tests in a vacuum belt dryer and a tray dryer are reported for typical tablet granulations. The data are analyzed to give estimates of total drying time, rate of drying, and overall heat transfer coefficient in each unit. It is concluded that vacuum belt drying of tablet granulations is much faster than tray drying procedures. Additional factors, such as capacities, operating costs and thermal efficiencies are reviewed and illustrate other advantages of the vacuum drying technique.

Vacuum drying can be a useful tool for solid products that are heat-sensitive. Here are some guidelines for the selection and use of various types of vacuum dryers.

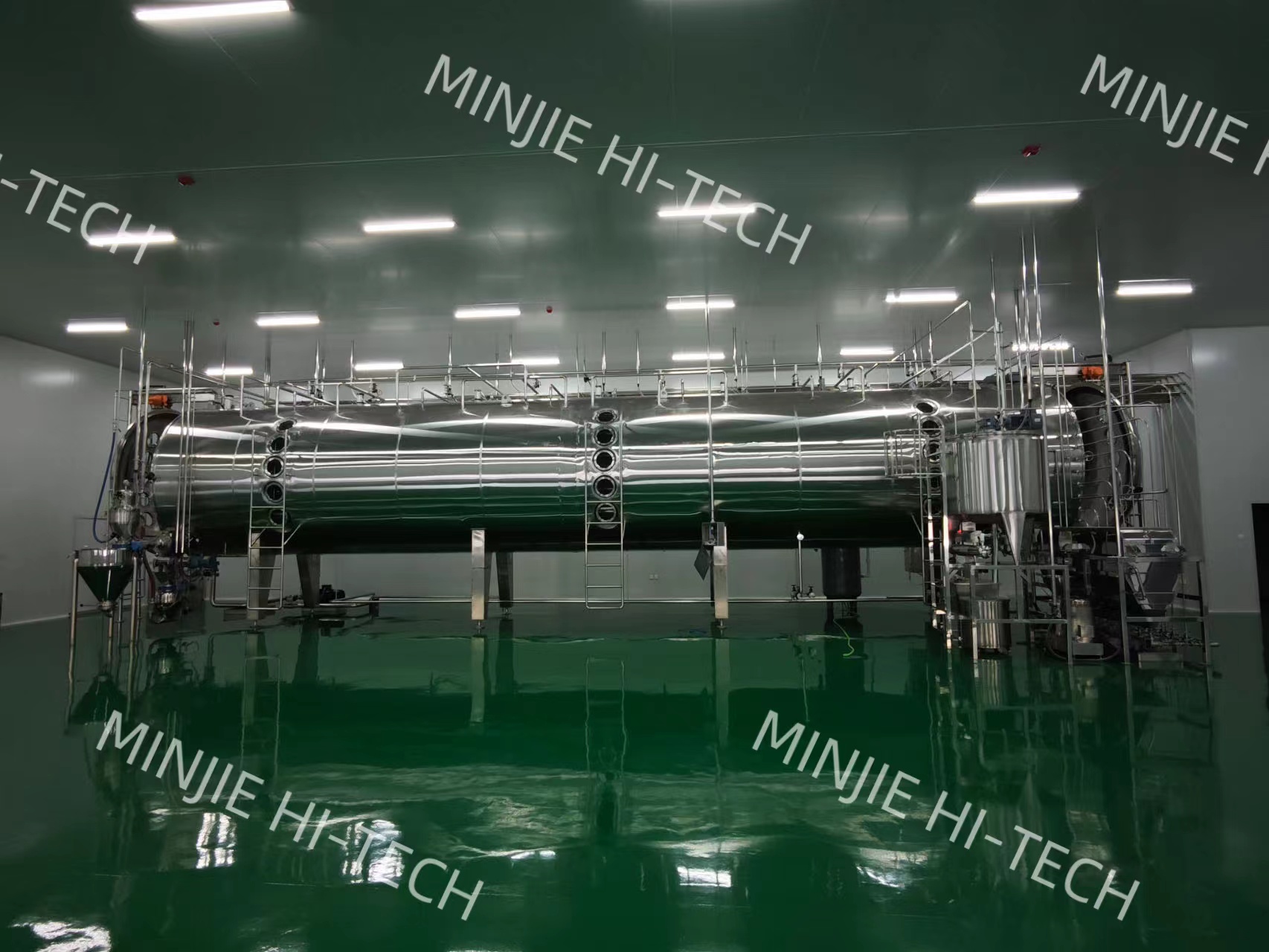

Drying is an essential unit operation in a variety of chemical process industries (CPI) sectors. Food, pharmaceutical, chemical, plastic, timber, paper and other industries use drying equipment to eliminate moisture during product processing. Most dryers are classified as direct dryers, where hot air (at near atmospheric pressure) is used to supply the heat to evaporate water or other solvents from the product. Another important dryer category, vacuum dryers, involves the use of a reduced-pressure atmosphere to surround the product.

Drying is among the most energy-intensive unit operations, due to the high latent heat of vaporization of water and the inherent inefficiency of using hot air as the (most common) drying medium. Depending on the specific product attributes required, different industry sectors require different types of drying technology. Drying high-value products that are likely to be heat-sensitive, such as food, pharmaceuticals and biological products, demands special attention. When dried by convection at higher temperatures, these heat-sensitive products degrade, change color and appearance and have lower vitamin or nutrient content. Vacuum dryers offer an alternate path.

Instructing Installation 04

Vacuum-drying advantages

Vacuum drying is a viable technology that has been used successfully for many years in the pharmaceutical, food, plastic and textile industries, among others in the CPI. A major advantage to vacuum drying is its energy conservation–less energy is needed for drying, cutting down on the economic and environmental protection.

The manufacturing of active pharmaceutical ingredients and intermediates require reliable and gentle treatment during solid-liquid separation with succeeding drying of the wet cake. Highly efficient contact vacuum dryers ensure effective drying performance and high operational reliability with low product degradation due to thermal and mechanical influences.

Free Trial Test 04

Contact Minjie: Caroline Li WhatsApp/Mob#: +86-18301902739 Skype:miamiaha Email Add: globalsales1@shmjjx.com