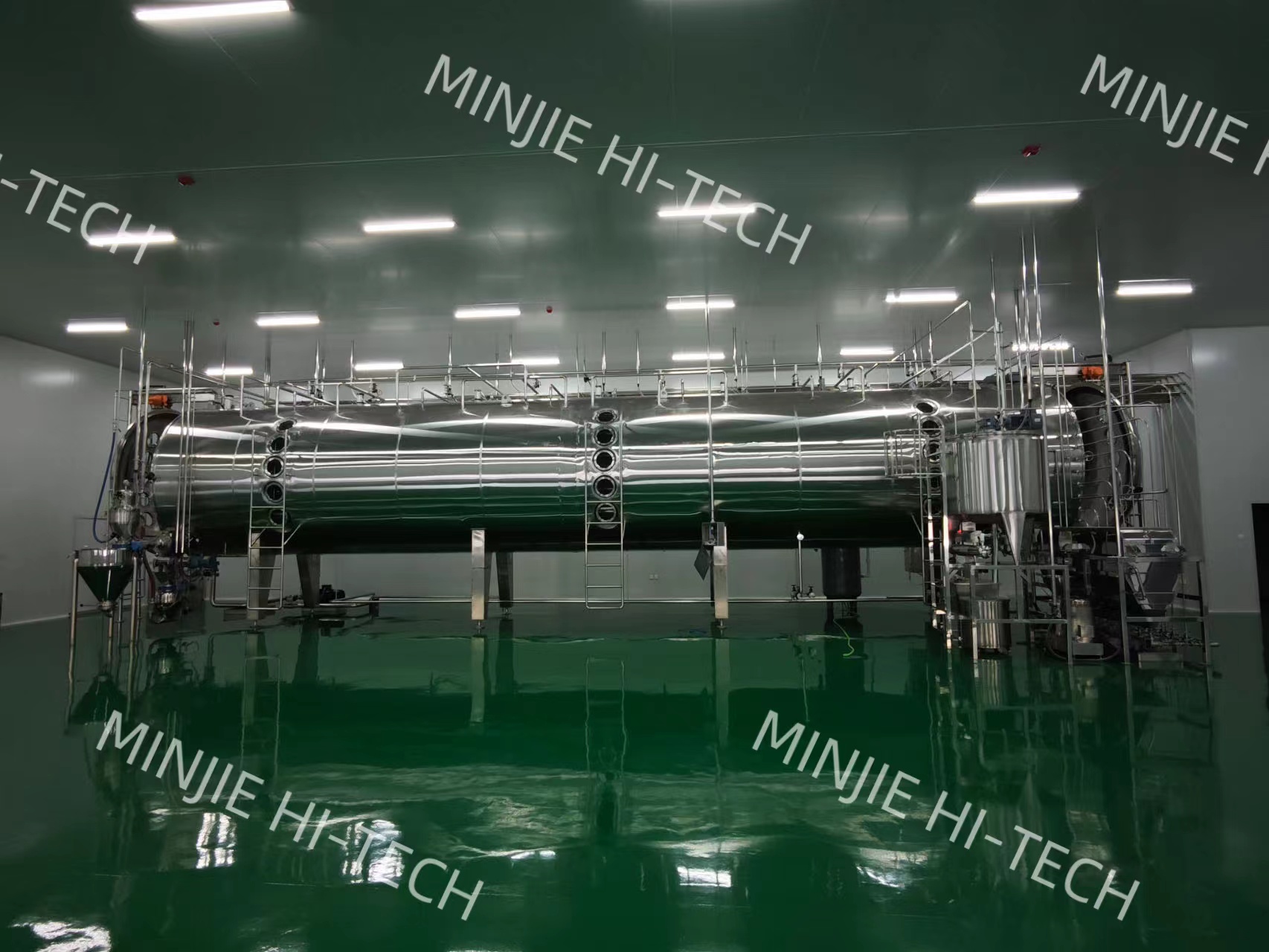

Founded and headquartered in Shanghai, China, established in 1957, Shanghai Minjie Hi-Tech Company has since grown to be a leading manufacturer of Vacuum Belt Dryer& SDR-Evaporator with its production facility in Shanghai. Its line of equipment serves a range of industries, including food processing, pharmaceutical production, plastics manufacturing, ceramics, metallurgy, and chemical processing. etc.

There are many industrial applications in which large volumes of powder or granules need to be dried and granulated before they can be packaged or mixed with other ingredients.

What is vacuum belt dryer?

Vacuum drying is a batch operation performed in an air-tight vessel. Using vacuum pumps, the pressure and humidity within the chamber are reduced. By lowering the atmospheric pressure within the chamber, the materials inside dry more quickly.

Vacuum drying heat-sensitive materials

Vacuum drying is one of the most suitable industrial drying techniques for heat-sensitive, hygroscopic, and/or toxic powders and granules. Avoiding excessive heat while drying powder may be necessary for a variety of reasons, ranging from product quality to safety:

Pharmaceutical powders – active ingredients may lose their medicinal effect when warmed.

Food drying – certain nutrients may break down if exposed to high temperatures. Taste, consistency, and appearance can also degrade under too much heat.

Plastics and chemical processing – synthetic materials can leach toxins with prolonged exposure to heat. This can even make convection drying methods hazardous, as the hot air stream must eventually be emitted.

Vacuum drying is a safe and highly efficient technique for drying large volumes of heat-sensitive powders or granules at a much lower temperature than would be required in a traditional industrial dryer. In a vacuum, where ambient pressure is reduced, the flashpoint of liquids lowers considerably.

Advantages of VBD:

- Continuous feed and discharge under vacuum state

- Pipelined, continuous and automated drying process

- Adjustable Drying Temperature 20-200℃

- 1/3 Running cost of traditional drying process

- Full enclosed and simplified process, no contamination

- CIP cleaning system, fulfill GMP requirement

- Drying time 20-150mins

- PLC control system

- Labor saving

- 95% Collection

Contact Minjie: Caroline Li WhatsApp/Mob#: +86-18301902739 Skype:miamiaha Email Add: globalsales1@shmjjx.com