Coffee is one of the three major beverage sources in the world. Coffee beans need to be extracted and concentrated, enzymatically hydrolyzed, and dried to obtain instant coffee powder. Due to the relatively complex processing process, it is necessary to have relatively reasonable technical and equipment support in industrial production. Shanghai Minjie Machinery specializes in providing instant coffee drying equipment. Can handle the material well.

The development of Shanghai Minjie’s instant coffee drying equipment is based on the needs of customers across the country. During the process of mass sales of vacuum cryogenic liquid continuous dryers, our company has obtained information on the needs of customers in the pharmaceutical, chemical and food industries across the country. Through communication with customers, we have learned about the current status of domestic solid powder particle drying. The problems of traditional drying technology have restricted the improvement of product quality and the development of enterprises, and we have also felt the pursuit of advanced drying equipment in these industries. desire.

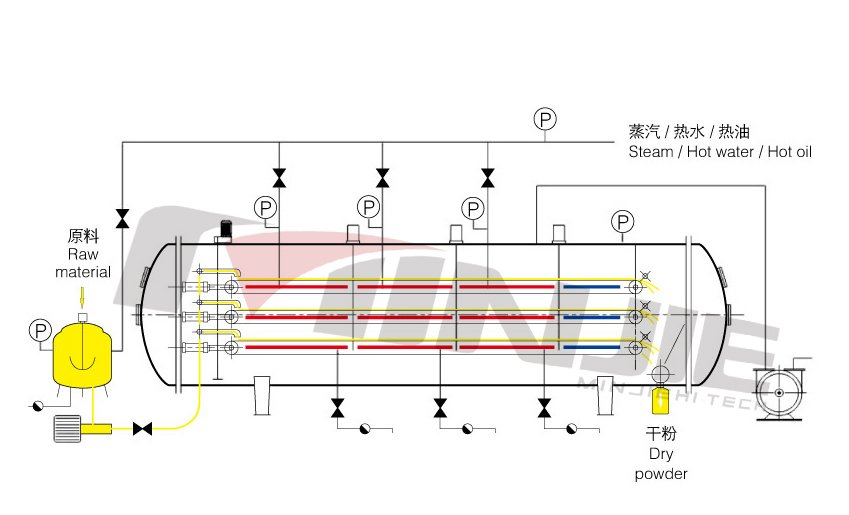

The working principle of instant coffee drying equipment:

According to the size of the customer’s production capacity, 3-11 layers of conveyor belts are designed and arranged in the vacuum container. Through the continuous solid feeder and the distributor, the raw materials that the customer needs to be dried are continuously fed under the vacuum condition, and they are evenly distributed for drying With the belt, because the material is constantly turning during the drying process, the evaporation speed and time are accelerated, and the uniformity of the product during the drying process is ensured. The drying temperature is adjustable at 20-150℃. The material enters the dryer and exits after drying. The material is adjustable in about 20-80 minutes. If the dried product needs a crushing process, it can be crushed under vacuum conditions to avoid flying dust, increase product yield and solve problems such as pollution. The dried product is continuously discharged through the vacuum continuous discharger and the vacuum receiver, and at the same time, the organic solvent can be recovered, which solves the environmental protection problem and increases the solvent recovery revenue.