More and more new energy industries pay attention on drying process for their products, such as:

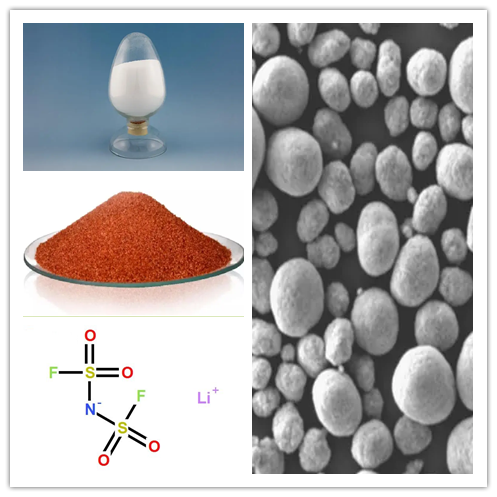

- Lithium salts: lithium hydroxide monohydrate &anhydrous lithium hydroxide drying

- Ternary precursor & High nickel ternary cathode material drying

- Cobalt sulfate, nickel sulfate and other metal salts drying

- Electrolyte additives, etc

| Ordinary Ternary Positive Electrode | V.S | High Nickel Ternary Positive Electrode | |

| Feeding raw material | Metal salt (Nickel cobalt manganese hydroxide) Lithium carbonate | Feeding raw material | Metal salt (Nickel cobalt manganese hydroxide) Lithium hydrate |

| Mixing & loading | Mixing & loading | ||

| One time sintering | Air | One time sintering | Pure oxygen |

| Coarse & fine crushing | Coarse & fine crushing | ||

| Sieving | Washing Dehydration | Deionized water | |

| Coating | Coating agent | Drying | |

| Loading | Sieving | ||

| Second sintering | Air | Coating | Coating agent |

| Sieving | Loading Second sintering | Pure oxygen | |

| Deironing | Sieving | ||

| Batch mixed packing | Deironing Batch mixed packing | ||

| Finished product | Finished product |

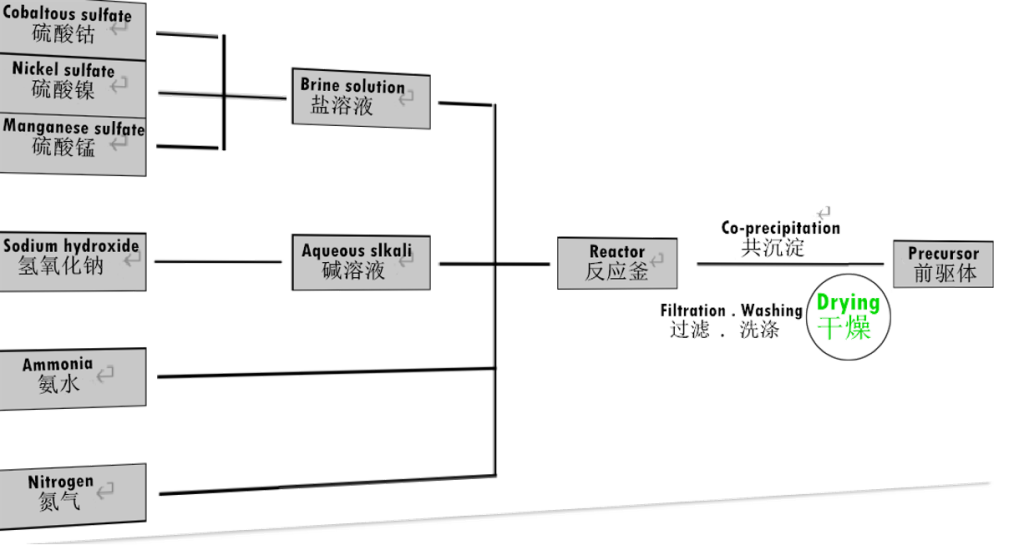

Precursor

The water content of the precursor after filtration and washing is 10-20%. The influencing factors of drying process include drying time, temperature and atmosphere. Under the condition of without increasing magnetic foreign matter, some problems can be avoid effectively by vacuum belt dryer, such as high temperature (< 150℃), easy oxidation and other requirements of the precursors.

Technological conditions of precursor preparation:

1. Ammonia concentration

2. PH value

3. Reaction temperature and duration

4. Solid content, composition content, impurities

5. Atmosphere of reaction

6. Stirring intensity

Drying process conditions:

1. Precursor particle size control (fine powder)

2. Crystal morphology control (structure)

3. Metal foreign body control (impurities)

Drying Method

- Tray/Disc Drying

- Paddle Drying

- Drum Drying

- Double Cone Drying

- Vacuum Drying

- Film Drying

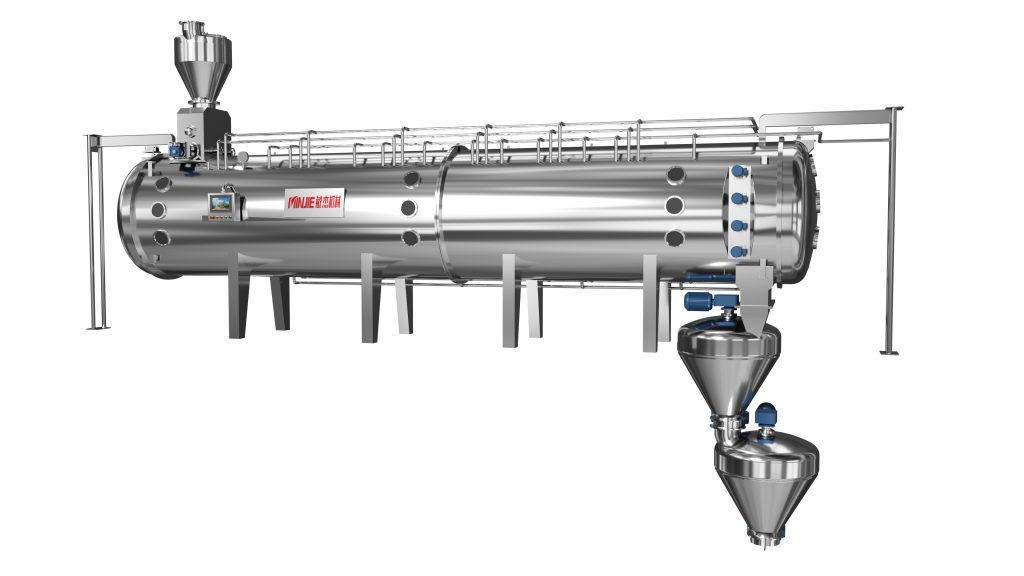

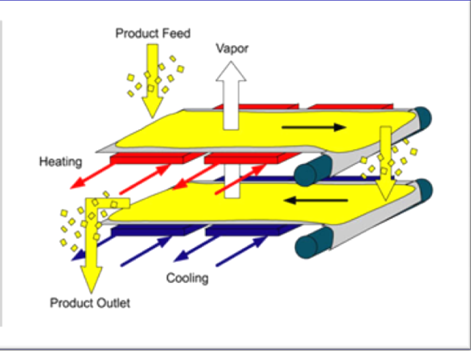

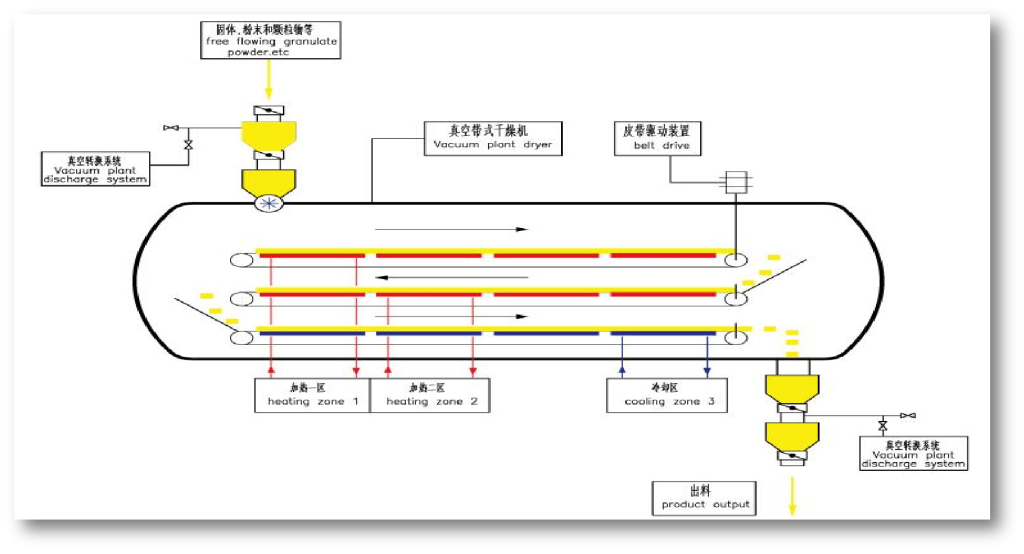

Features of Vacuum belt dryer:

- Effective control of magnetic foreign bodies and metal impurities in terminal products

- During the whole drying process, the material is in a relatively static state to preserve the crystal shape of the product to the greatest extent

- Continuous drying, gradient heat transfer, all on-line parameters controllable

- The drying time is short (60-150min) at the temperature allowed by the product (40-250℃)

- Clean, pollution-free production conditions and online recovery of organic solvents (continuous drying, closed system, effective in-place cleaning)

- Drying under vacuum environment, reducing the entry of carbon dioxide, ensuring the product quality

Some of questions about Tray/Disc Dryer

Some of questions about Tray/Disc Dryer

Is disc drying a gentle process?

—No, because the product can be damaged for the following reasons:

- The mechanical stress caused by the rotary rake increases the risk of magnetic foreign matter and metal impurities

- In the process of material moving along the helix, a small amount of material is overheated and deteriorated, forming hot spots, increasing the difficulty of cleaning

- During the feeding process, wet materials may fall directly into the chassis, resulting in unqualified moisture

- During the operation of whole equipment, a small amount of material dust tend to float on the top of the machine, resulting in material backmixing

Drying with vacuum belt equipment is a gentle process

- The product is placed on a smooth band

- Drying process without mechanical pressure

- Suitable for granule, powder material

- Eliminate magnetic foreign bodies and metal impurities at the end products

SHANGHAI MINJIE has become a leading manufacturer of Vacuum Belt Dryer & Evaporator since established in 1998.

For any enquiries, please contact: Caroline LI

Email address: globalsales1@shmjjx.com

Mob # /Whatsapp: +86 183-0190-2739