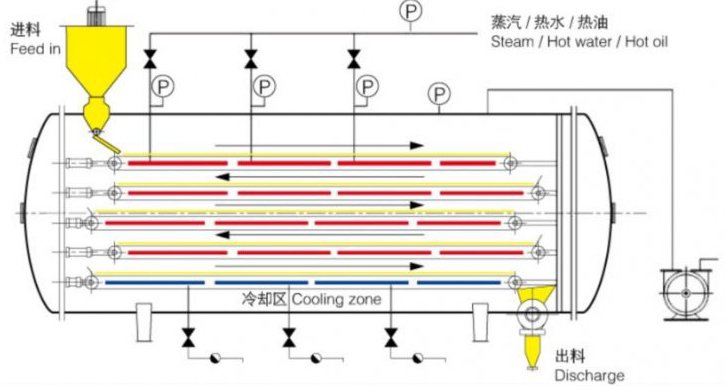

Principle of potato starch drying equipment:

Potato starch drying equipment is a new type of drying equipment that completes continuous feeding and continuous discharging under vacuum conditions. The equipment is used to feed the material into the vessel in the vacuum environment by the feeder, and the distributor is evenly distributed on the conveyor belt. The way of distributing can be selected according to the characteristics of the material. When the material is conveyed from the conveyor belt to the end, lower belts run in the opposite direction of upper belts, and the material falls into the second layer of conveyor belt, and then continues to be conveyed back by the conveyor belt, and so on. Finally, the material is discharged after drying. The temperature can be adjusted according to the characteristics of the materials. If the materials are heat-sensitive materials, lower the temperature and slow down the speed of the conveyor belt. For special materials that cannot contact air, such as chemical raw materials, they need to be directly received by the vacuum tank when they are discharged.

Because the temperature, vacuum degree, and drying speed are all adjustable, the dried product is superior to other drying equipment in terms of color, humidity, and product performance, so this equipment is also widely used.

The path of potato starch drying equipment:

Suitable for drying various materials such as food, chemicals, medicines, etc.

Various vegetable soups, yeast extract: carrots, beets, celery, onions, garlic, tomatoes, condiments, beef bones, pork bones, chicken extract, instant soup mixtures, yeast, rhubarb, various proteins (amino acids), etc.;

Juice (fruit) concentrate-non-alcoholic beverages, pastries: beverages, pastries, ice cream, cakes, yogurt, etc., fruit juice powder (apple, pear, apricot, orange, grape, lemon, papaya, mango, etc.) , Black rice fruit, pectin, etc.

Chemical products: synthetic lysine (L lysine), anti-biomass, powder natural paint

Products containing cocoa and sugar: milk powder, coffee, high-calorie fruits, saccharin, sweeteners, chocolate (cocoa)

Enzymes, vitamins, beer brewing aggregates, intermediate products: amylase, intermediate products of vitamin roots, intermediate products of natural vitamin roots, natural vitamin mixtures, brewer’s yeast, malt extract (maltose, wort), Hop essence

Medicinal plant essences: Chinese medicine essence, aloe vera, tonic agents containing various vitamins, horse chestnut fruit

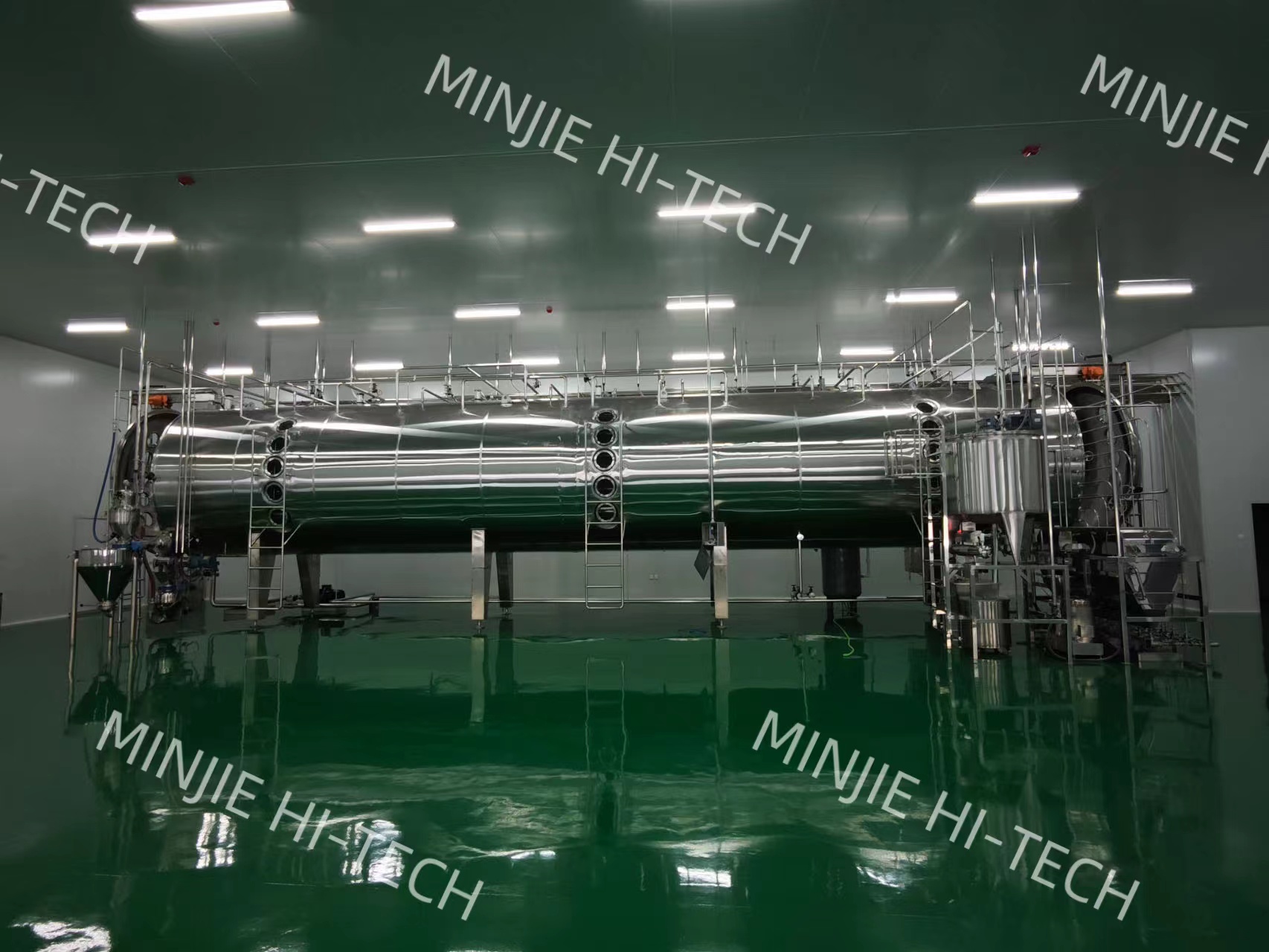

Potato drying equipment is supplied in complete sets, with good service and easy installation and use, so that users can install them in the shortest time and put them into production to achieve the best benefits.