There are many ways to dry tea powder, but after many experiments, to maintain the color and flavor of tea powder and dry degree, vacuum dryer is the most effective way.

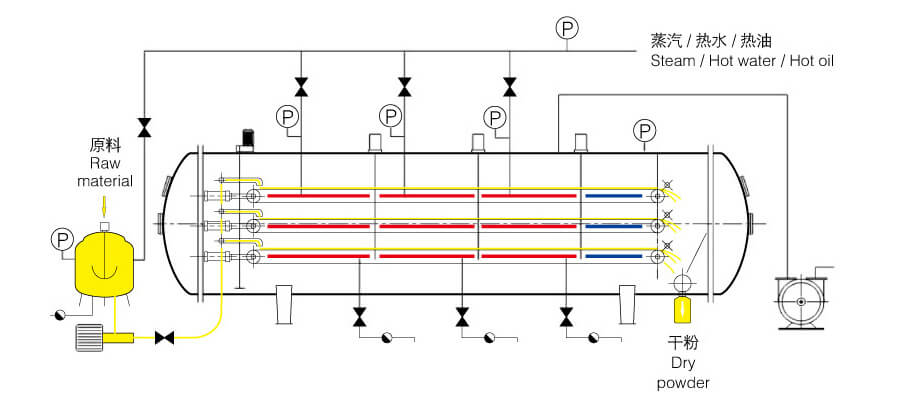

Vacuum Dryer:

Vacuum drying equipment can make dry products retain the original flavor and material characteristics, no product oxidation (no color/odor loss and stale), good appearance. Because it is vacuum drying at low temperature, it can meet the drying requirements of heat-sensitive and active materials, break through the technical problem of continuous material inlet and outlet under vacuum condition, transform static drying into dynamic drying, greatly improve the output of dried products and reduce energy consumption.

The continuous low temperature vacuum belt dryer can tackle technical issues other drying equipment is face, especially for the high viscosity material drying, high fat materials with high sugar and high heat sensitivity. The controllability of all process operating parameters ensures the stability and consistency of product quality.

Scope of Application:

1, pharmaceutical industry: such as Chinese medicine extract dryer, vitamins dryer, antibiotics dryer, active substances dryer, fermentation liquid dryer and other drying.

2, plant extraction industry: such as natural product extracts drying, biological products and other drying.

3, food industry: such as malt extract drying, rice protein powder drying, milk powder drying, tea powder drying, food additives drying, flavoring from vegetables drying, hop extracts drying, instant drinks drying, vegetable concentrate drying, condiments drying, instant soup, broth, vegetable protein, chocolate and semi-finished products, meat extract and other dry.

4, chemical industry can be applicable.

SHANGHAI MINJIE has become a leading manufacturer of Vacuum Belt Dryer & Evaporator since established in 1998.

For any enquiries, please contact: Caroline LI

Email address: globalsales1@shmjjx.com

Mob # /Whatsapp: +86 183-0190-2739