In the field of fruit and vegetable powder processing, the choice of drying technology directly determines the retention rate of nutrients, color, flavor and production efficiency of the product.

Shanghai Minjie Machinery Co., Ltd. has innovatively developed a vacuum low-temperature continuous dryer, which, with its core advantages low-temperature drying and continuous production, has completely solved the industry pain points of traditional spray drying and freeze drying, bringing higher quality and better benefits solutions to fruit and vegetable powder enterprises!

Traditional Drying Limitations VS Minjie Vacuum Low-Temperature Continuous Drying Breakthrough 1. Low-temperature drying, preserving active to the fullest Spray drying: Requires high temperatures (150-200℃), which can easily lead to a large loss of heat-sensitive (such as vitamins, polyphenols), and products are prone to scorching and discoloration.

Vacuum Freeze Dryer

– Freeze drying: Although it can preserve nutrients at temperatures, it has high energy consumption, a long cycle (20-40 hours), and limited production capacity.

– Minjie’s solution: Contin dehydration in a low-temperature vacuum environment of 40-60℃, effectively protecting the natural color, flavor, and active ingredients of fruit and vegetable powders, a retention rate of nutrients that is 50% higher than spray drying!

2. Continuous production, efficiency and cost win-win Traditional freeze drying batch operations, with multiple manual interventions and low production capacity; spray drying, although continuous, has enormous energy consumption. – Minjie’s innovation: Through intelligent continuous, drying, and discharging design, 24-hour uninterrupted production is achieved, with an efficiency improvement of 3-5 times compared to freeze drying, and 30% reduction in comprehensive energy consumption!

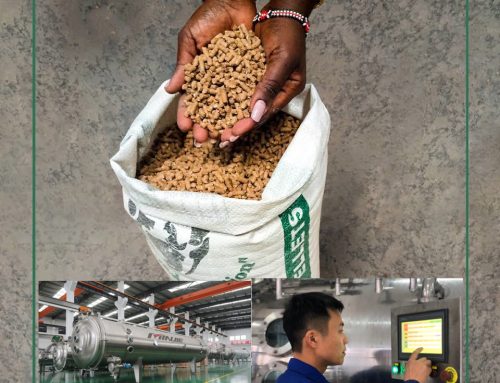

3. Quality upgrade, opening up the high-end market – Good product solubility, uniform particle size no scorching problem of spray drying, no multi-porous structure of freeze drying that absorbs moisture, and is more conducive to long-term storage and transportation Application scenarios: Suitable for the processing of high-value-added fruit and vegetable powders such as strawberry powder, blueberry powder, spinach powder, etc., in line with the fields of health products and infant complementary food that are strict about quality.

Contact information :

mail: tmj@shmjjx.com

whatsapp:86-13917588675